To Ilocanos, their very own native vinegar or the locally known sukang iloko is one of the many staple cuisine products primarily because of its role in the Ilocano culture and history particularly as their food condiment or food preservative. Sukang iloko which is made from naturally fermented sugarcane, has a strong acidic scent and turbid-color quality distinctive of other vinegars. Its unique taste complements mouth-watering delicacies such as adobo, paksiw, longganisa and a perfect match for empanada.

One of the major vinegar producers and manufacturers in the province of Ilocos Norte is the Malampa Agrarian Reform Cooperative (MARC) located in Brgy. Nambaran, Bacarra. Its members are farmers who have maintained various economic activities like palay trading, relending and of course, vinegar and basi production.

The story of the vinegar business of MARC has come a long way since it started in 2005. Before the vinegar production business cooperative was established, some farmer-members are already producing vinegar in limited volumes and generally of lower quality for their own personal consumption. They were apprehensive that they will not be able to market their products. Still, DTI and Department of Agrarian Reform (DAR) saw the big market potential of Sukang Iloko for the cooperative so they assisted and encouraged its members to engage in a large scale vinegar production.

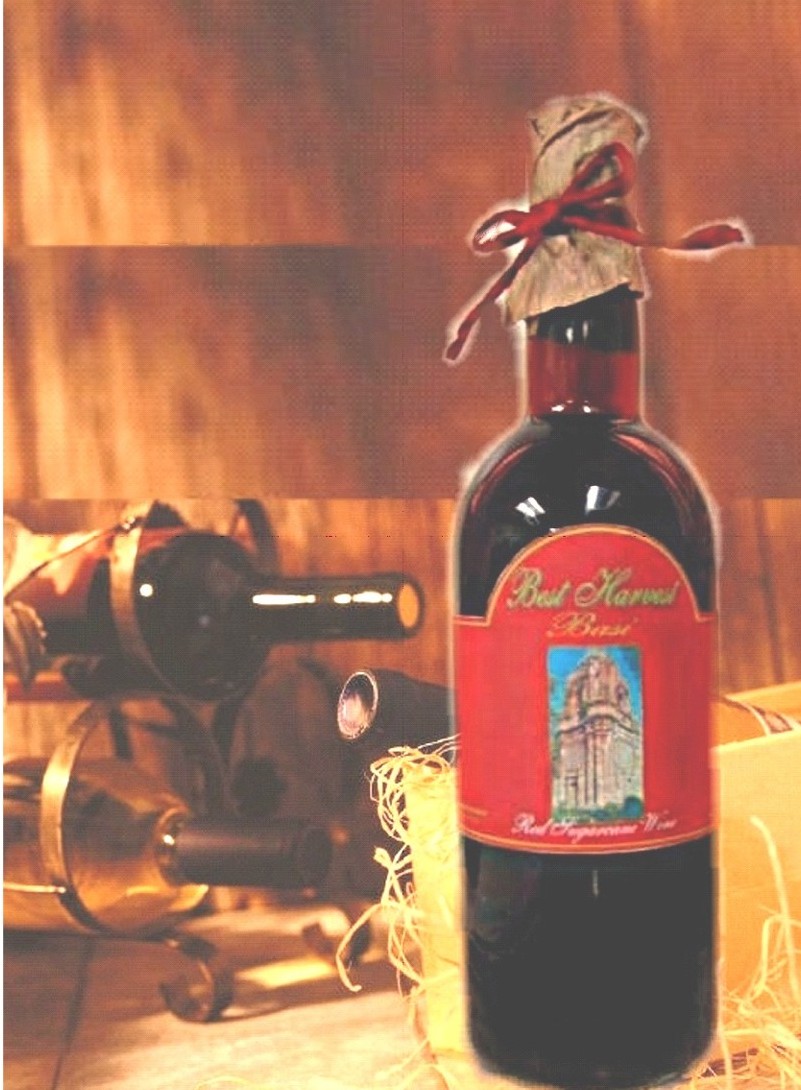

MARC served as the marketing arm of the produce of the member-farmers engaged in the manufacture of vinegar which they later on named as La Torre Iloko Vinegar. With the support of DTI, DAR together with all the other stakeholders, the cooperative came up with a marketing plan to support the implementation of the project. The assistance of the Department of Science and Technology (DOST) and the Department of Agriculture (DA) were also sought in order to address the technical aspects of the proposed project.

To further enhance production, equipment were provided to them by different government agencies. Though DTI’s Shared Service Facility Project (SSF) and Bottom Up Budgetting (BuB), a total of PHP 2.5 million worth of equipment were given to MARC. The provision of these projects enabled the cooperative to produce better quality and market driven products. Aggressive promotion and linkage with private institutions also helped in widening their market. Due to the improved packaging and labeling undertaken by all stakeholders, the product has gained market demand not only in the Province but to other places as well. Initial interventions were made with the different restaurants and groceries in Tuguegarao and has also tie-up with a dealer from Metro Manila.

With the support of LGU, the La Torre Iloko Vinegar is now adopted as the One Town One Product (OTOP) of the Municipality of Bacarra. The OTOP is a priority program of the government to promote entrepreneurship and create jobs. It supports micro, small and medium enterprises (MSMEs) to manufacture, offer and market distinctive products or services through the use of indigenous raw materials and local skills and talents.

It was envisioned that the Vinegar Project did not only present opportunities that increased the income of the household, nor a stop-gap measure in the short-run, but more importantly provided sustainability that served as the vehicle to uplift the economic conditions of the people of Nambaran. With the continuing development of their entrepreneurial and managerial capabilities, the officers and members of the cooperative is now serving as inspirations to their community. A proof that even farmers can manage the operation of a business.

With these projects and the continued support of the stakeholders, the members of the Malampa Agrarian Reform Cooperative can only look forward to a better future.